flowcoating

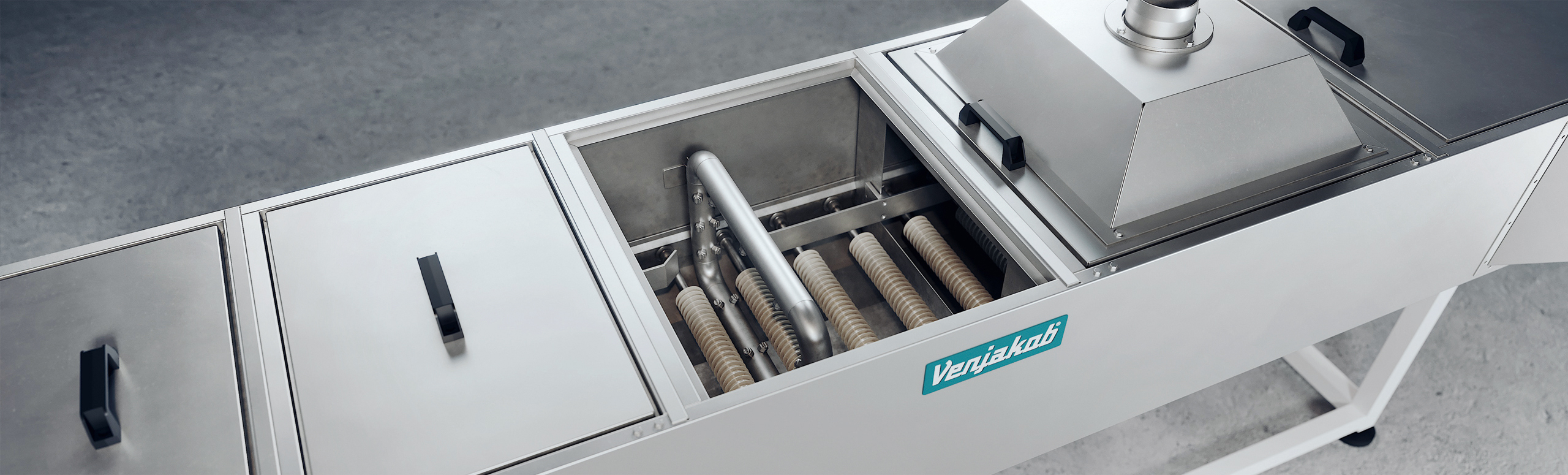

Flowcoating for effective coating on four sides

There are two types of flowcoating: continuous and immersion. Large quantities of coating medium flow over the workpieces. The flowcoating method achieves an efficient degree of application, and any excess material is blown off at the outlet and can then be processed and reused.

Flowcoating applications

Flowcoating is suitable, in particular, for waterproofing, varnishing, and priming applications with low solid content. You can also use the flowcoating method to coat wooden parts that, because they tend to float, are not suitable for dip coating. Our customers often use the flowcoating method to coat outdoor window components, construction profiles, and moldings and profiles.

The flowcoating method: what distinguishes Venjakob system concepts

In combination with the excess method, our flowcoating systems offer a highly effective, sustainable solution for coating or waterproofing your workpieces. Any excess coating medium is blown off the workpiece and can then be filtered and processed for reuse. Venjakob’s flowcoating technology delivers high throughput as well as application efficiency of nearly 100%. Built to be high-quality, our systems require minimal maintenance and offer high system availability. Applications based on the cost-effective flowcoating method with Venjakob technology are eco-friendly, economical, and reliable!

- Application

- area of application

- process flow

- advantages

Application +

Application of

- Low-solid coating materials

- Impregnations

- Glazes

- Primers

area of application +

Application areas of the flooding method

The flooding process is particularly suitable for coating wooden parts that are not suitable for the dip coating process due to their tendency to float. These include:

- External window parts

- Building profiles

- Profiles & Battens

process flow +

Process flow example for a flood coating

- Feeding with individual parts (manually or automatically) or feeding from existing production line

- Coating by the surplus process

- Recovery via blow-off unit at drip position with return to the immersion tank

- Drying in the downstream four-sided dryer (from below and above)

- Removal of the workpieces - manually, automatically or transfer to a production line

advantages +

Advantages of the flooding method

- Simple machine for high throughput rates

- Order efficiency of almost 100%.

- Suitable for materials that float

Let our competent contact persons advise you on possible systems in a personal conversation!

Your contact person