UV curing system by venjakob

Drying Ovens for UV Curing Systems or Adhesives

UV curing systems use intensive UV irradiation to cure in mere seconds. These systems require very little space and shorten your production processes. The number of lamps required is dependent on the type of substrate to be applied, the throughput speed, the quantity to be applied, and the workpiece geometry. Venjakob offers UV curing systems with traditional gallium, mercury, and iron doping as well as with LED technology.

What Distinguishes Venjakob UV Curing Systems

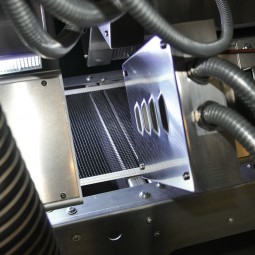

Our industrial UV curing systems offer minimal wear and tear and feature UV lamps with a long service life. If they need to be changed, they’re easy to access and replace thanks to the modular design. Venjakob UV curing systems can help you achieve homogenous material surface curing. Our technology is also especially gentle on your workpieces. Reducing the amount of IR in the UV light (cold mirror) minimizes workpiece surface heating, which is especially advantageous when working with temperature-sensitive materials.

The modular design of all Venjakob systems offers you maximum flexibility, and UV modules can be expanded at any time. The temperature of the exhaust air in our UV curing system is regulated, which in turn will reduce your operating costs.

application example

Powerful, Energy-Efficient UV Curing

Venjakob’s UV curing systems feature performance-optimized UV lamps with emission spectrums that are suitable for the coating in question. In combination with high-performance UV lamps, sophisticated electrical ballasts ensure safe, reliable operation. Our powerful UV industrial ovens can be equipped with lamps featuring different types of additives (Hg, Ga, Fe, etc.) as well as with LED technology. They’re energy-efficient and have a high energy density for each centimeter of lamp length.

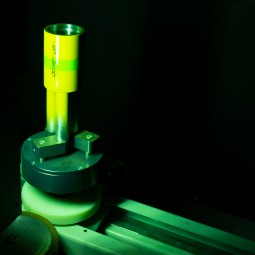

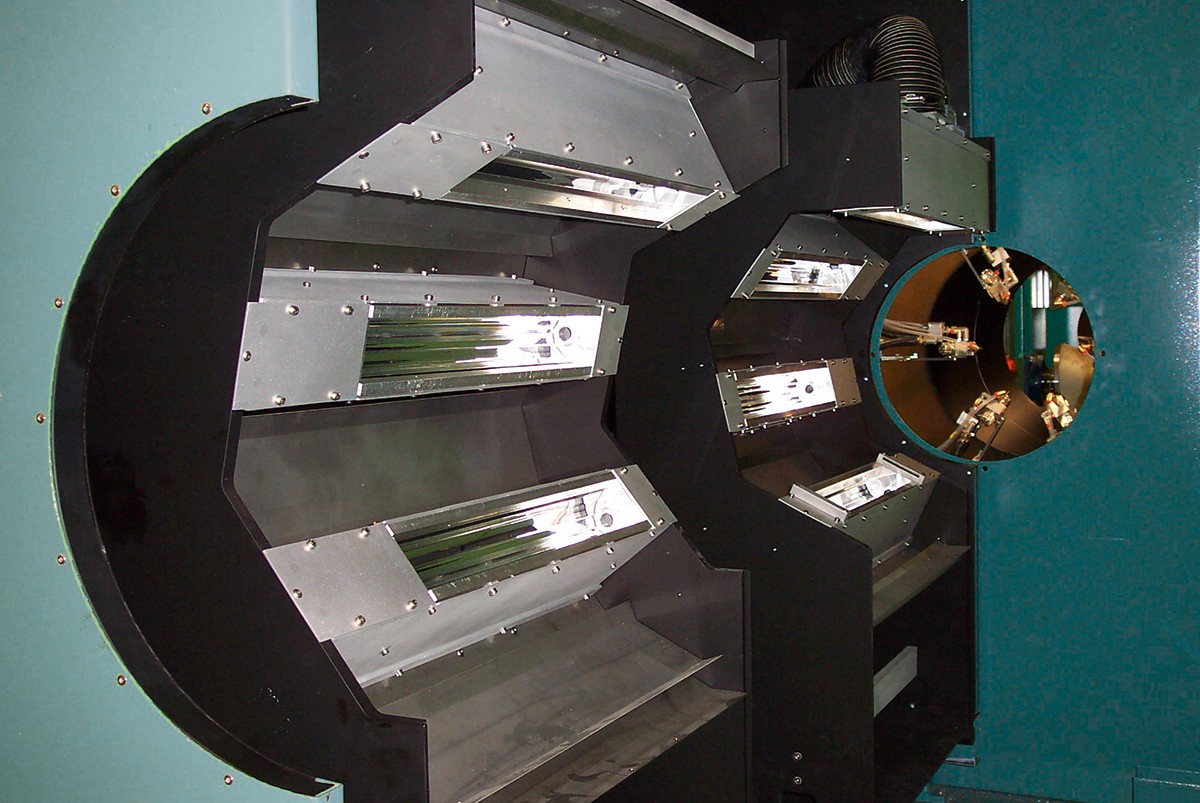

Special Venjakob Surround UV Technology: Benefits and Features

The internally developed surround UV technology with special reflector geometry guarantees exceptional curing of workpiece edges. Venjakob’s special surround UV technology uses corresponding reflectors to prevent direct UV irradiation of the workpieces, achieving outstanding three-dimensional workpiece irradiation and minimizing the increase in temperature of the parts.

Highly reflective, optimized lamps use energy efficiently, while specially developed reflectors enable continuous curing of workpiece surfaces and edges. Clear coatings usually require just one lamp – color coatings two. This technology reduces energy consumption by more than 20% compared to conventional technologies.

- Area of application

- process UV-Technology

- process LED-UV-technology

Area of application+

Venjakob’s UV Curing Systems Are Versatile

- UV coating medium (Water and solvent-based UV coating, high-solid UV coating, color and transparent)

- Suitable for workpieces made from wood, plastic, glass, construction materials, and metal

- Excimer technology (frosted effect)

process UV-Technology+

Benefits of the UV Curing Method

- Extremely short curing times

- Immediate further processing

- High degree of gloss

- High scratch resistance

- Especially resistant to chemical exposure

process LED-UV-technology+

Curing 3D Workpieces with LED UV Technology

Venjakob innovatively incorporates LED technology into the segment of 3D curing. You’ll be impressed by the minimal thermal stress on workpieces and the optimized energy consumption.

The building air is not exposed to ozone, as is the case with conventional UV technology – and the longer service life of the LED lamps optimizes your energy balance.

The Benefits and Features of Venjakob LED UV Curing Systems

- No shutter required

- Lamps with a much longer service life

- No reflector necessary

- Significant energy savings in comparison with traditional medium-pressure UV systems

- Individual LED segments can be turned on and off to adjust the width control of the lamps

Let us advise you on the possible applications in a personal conversation!

Your contact person