- Venjakob

- Automation

- Material handling

Material handling technology

Finely tuned conveyors and material handling technology for optimal material flow

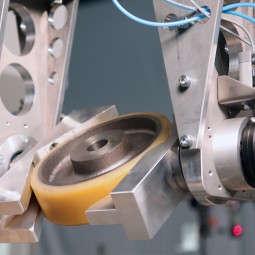

When it comes to handling technology in the field of mechanical engineering, conveying parts safely and effectively is a top priority. The individual material handling technology also needs to take a lot of criteria into account: the workpiece formats, the material structure, and the distances to be covered. Additional aspects such as short drying distances and maximum conveyor capacities can have a key impact on the development of an effective, professional transport solution. Venjakob develops and produces conveyors for complete production lines or as an individual system. Each solution corresponds to the specified requirement profile.

Venjakob material handling: transport solutions for extreme requirements

The extensive variety of Venjakob system technologies enables a wealth of effective solution components that speak for themselves. Continuous conveyors, patented curve conveyors, and complex angular transfers offer highly reliable solutions for continuous workpiece transport. For tasks that require a flexible workpiece carrier system, spindle chain/chain-on-edge and skid conveyors can carry out defined processes with continuous or clocked transport. All of the transport solutions are designed for extreme requirements and operate in high temperature ranges up to 450°C and in explosive atmospheres.

Handling technology: professionally optimizing handling

Venjakob has been active in system engineering for many years now and develops efficient handling technology. Our handling systems ensure professional optimization of handling. In addition to safe and effective transport of workpieces, automating and optimizing repetitive handling tasks also provides high rationalization potential. We offer you innovative solutions with impressive efficiency in production and thus increase your competitiveness. Perfectly coordinated processes and the professional interplay between person and technology promote work satisfaction and company success.

Venjakob´s handling systems are in use all over the world

When it comes to rotating, turning, forwarding, stacking, loading, collecting, separating, and allocating, solutions can often assume several functions. You’ll find sophisticated, tailored Venjakob conveyor and handling concepts, for example, in the automotive, building material, casting, wood and furniture, plastics, glass, leather, metal, and supply industries. The tried-and-tested conveyors and handling systems that Venjakob develops as individual tasks or integrates into its coating machines and dryers complement the industry knowledge acquired through the planning of countless projects. They’re exactly why Venjakob’s standards are valued the world over.

Venjakob is your experienced, expert contact for everything related to conveyors, from the planning and construction to manufacturing and installation of turnkey systems. Intelligent robotics and automation in handling technology are now an integral part of each and every modern facility. Tailored specifically to your requirements, our products are highly reliable, economical, durable, and easy to maintain.

We are looking forward to your contact request!

Your contact person