- Venjakob

- Applications

- Construction Elements

coating construction elements of all kinds

Coating solutions for durable products – more than just window and stairs painting system

Venjakob is the specialist in the production of high-quality industrial systems for treating the surfaces of any and all components. Stairs and windows are only an example. With many years of experience and solutions across all sectors, we manufacture coating machines that allow you to treat any of the construction elements used in your production processes. In the field of coating applications, we can offer you an enormous portfolio of coating systems that allow you to coat materials of all shapes and sizes.

Among the components are

- Window individual part painting

- Stair construction

- Sectional doors

- Interior and exterior doors

application spectrum

Latest technologies for time and cost saving coating of construction elements

System concepts individually tailored to your production conditions and manufacturing needs accelerate your operational processes and guarantee a high-quality and consistent output of excellently coated components. With modern painting systems you have the possibility to achieve excellent painting and application results thanks to precise control and trend-setting functionalities. And this again and again and with consistently high quality. Work with fast colour changes for individually manufactured elements and coat high-quality components with our painting systems.

STAIRS

Stairs consist of a wide variety of components and are coated in a wide range of colours. The steps in particular must be particularly hard-wearing. Venjakob offers customized solutions for small batches up to serial production.

WINDOWS

Venjakob is specialized in the production of window components.

This includes roof window and facade frame systems. We realise single part painting for components with various corner joints. In our systems, the workpieces are painted lying on their sides. Impregnation, priming, top coat - the entire process from one source!

INTERIOR|EXTERIEUR DOORS

From series production to individual door systems with milled patterns. By using coating robots, it is possible to prime and paint profiles| milling individually in advance. Venjakob offers coating lines for different door sizes. Certain Venjakob line technologies allow double coating of the outer edge in a continuous flow as well as the possibility of combining roller priming & spray painting applications

SECTIONAL GATES

Sectional doors for outdoor use are coated in a wide range of colours on our systems. Due to the required high resistances, 2 K paint systems are usually used.

SUCCESS STORY - EDGE COATING SYSTEM

For accurate and environment-friendly door edge coating

Based on a prototype, Venjakob has developed a modular, automatic CNC-controlled edge spraying system for coating the longitudinal edges of specialized doors with double rebates, single rebates and blunt edges on both sides in through-feed operation. A movable jig system, that can be adjusted with the aid of recipes, protects the door panels from coating material overspray to the greatest possible extent. This reduces cleaning solution use by 15 to 20 tons per year. Yet another challenge was posed by the contract, which had to take into account both Anglo-American and European law - just another way in which Venjakob’s support proved invaluable.

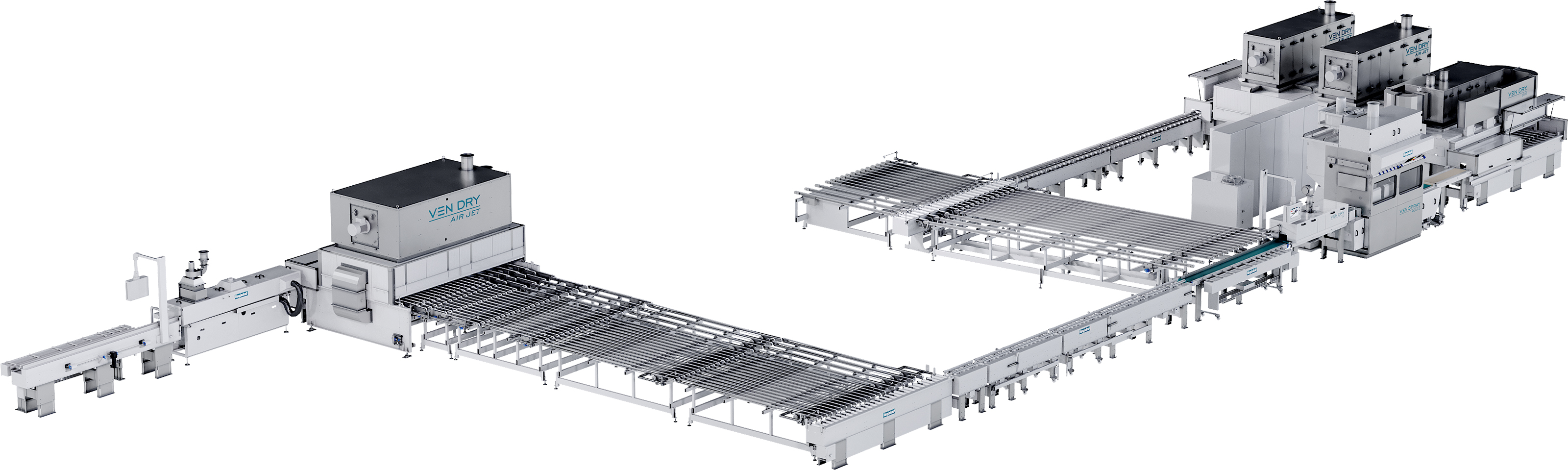

Success Story - Flexible surface coating

Flexible surface coating in batch operation

Cost awareness, quality aspects and greater flexibility in the production process were important reasons for the Swiss company RWD Schlatter to perform surface processing in-house. The requirement was a highly dynamic and flexible surface processing center with a significant degree of automation.

SUCCESS STORY - COATING OF WINDOW COMPONENTS

Fully automatic coating of individual window components allows fast and flexible production

Venjakob has developed a fully automatic coating system for the Norwegian window manufacturer Gilje Tre for coating window frames with modern water-based coatings. The system concept is geared towards the highest production efficiency, the fastest possible drying time and in terms of parts logistics, towards maximum output.

SUCCESS STORY - STAIR COATING SYSTEM

AUTOMATIC STAIR COATING SYSTEM

The new automatic coating system for a medium-sized carpenter’s workshop coats workpieces with water-based UV coating materials and water-based stain in an environment-friendly manner and offers quick drying times as well as high surface quality.

SUCCESS STORY - DOOR FINISHING LINE

RESOURCE-FRIENDLY DOOR FINISHING LINE

Environmentally friendly and resource-saving finishing with a simultaneous increase in production requires the use of new technologies or an intelligent combination of patented technologies and processes. For the door manufacturer Garant, Venjakob as general contractor has created a door coating line that relies on a new circulating air process with state-of-the-art spraying technologies.

SUCCESS STORY -

combined roller and Spray coating

COMBINED ROLLER AND SPRAY COATING LINE FOR PREMIUM WHITE LACQUER DOORS

Faster and more resource-efficient production

The combination of rolling and spraying process, including turning and return of the workpieces, comprises 14 production steps. The system was designed in an U-shape.