- Venjakob

- News & Events

- Exhibitions

- THE BATTERY SHOW 2024

Battery show north america | October 7-10,2024

Huntington Place | Detroit, Michigan

Join us at North America’s Largest Advanced Battery and H/EV Event Show in Detroit!

We are a part of the German Pavillion. Our staff at booth # 4222 is looking forward to welcoming you!

ALREADY KNOWN?

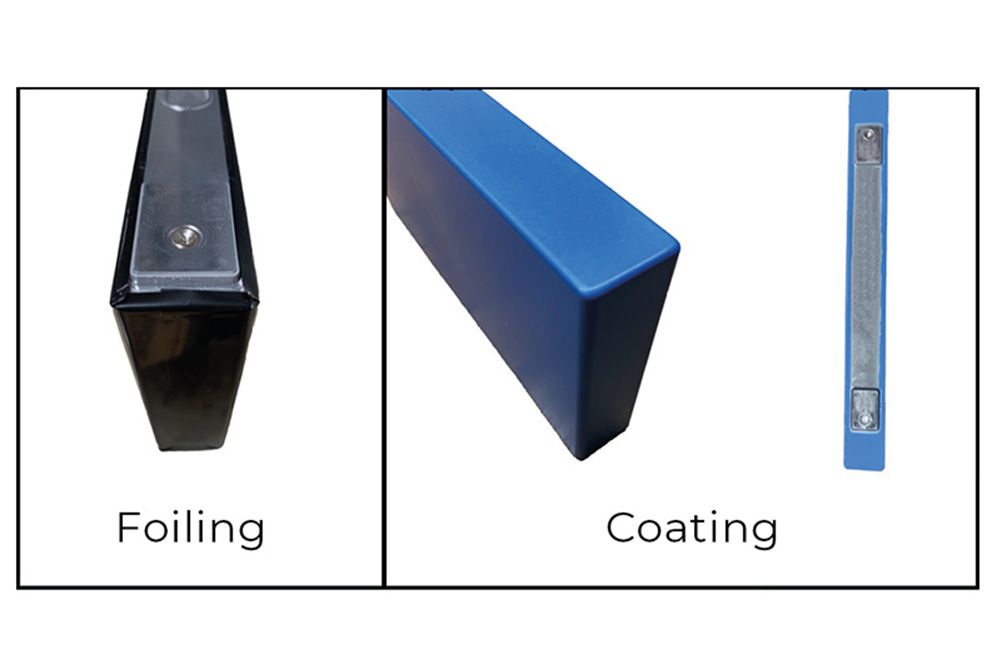

Battery cell coating replaces film wrapping process

The spray coating system from Venjakob replaces more cost-intensive film wrapping of battery cells. Have you heard about it?

This new process of coating and curing the battery cells with 100% UV lacquer in a single pass increases production speeds and reduces the comparatively high costs associated with the previous foiling process.

Technical challenges, golas and highlights at a glance:

- 6-sided coating of battery cells in different battery cell formats

- battery cell formats without retooling

- reliable all-round protection of the cell edges

- increased production speed

- paint recovery, reduced paint consumption

- no handling / turning / gripping

- no damage to the battery cells

Battery cell coating instead of foiling offers many advantages.

Test results from independent institutions demonstrate that the UV coatings outperformed the adhesive films in both mechanical and electrical tests, especially under end-of life conditions. This indicates that UV coatings represent a promising alternative to the commonly used adhesive films, especially for battery systems designed for long-term durability in challenging environmental conditions

Various analyses confirm the high effectiveness of the innovative insulating coating, which achieves adhesive strength values of over 15 MPa in tensile shear tests.

foiled and painted battery cell

The coating encloses and protects the sensitive battery cell more reliably than the film wrapping.

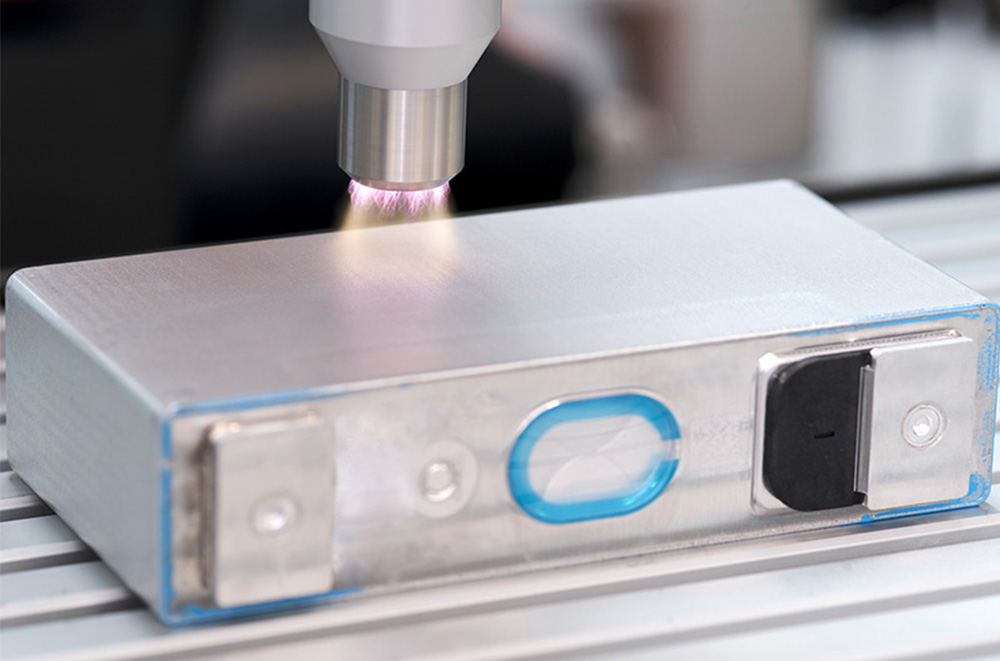

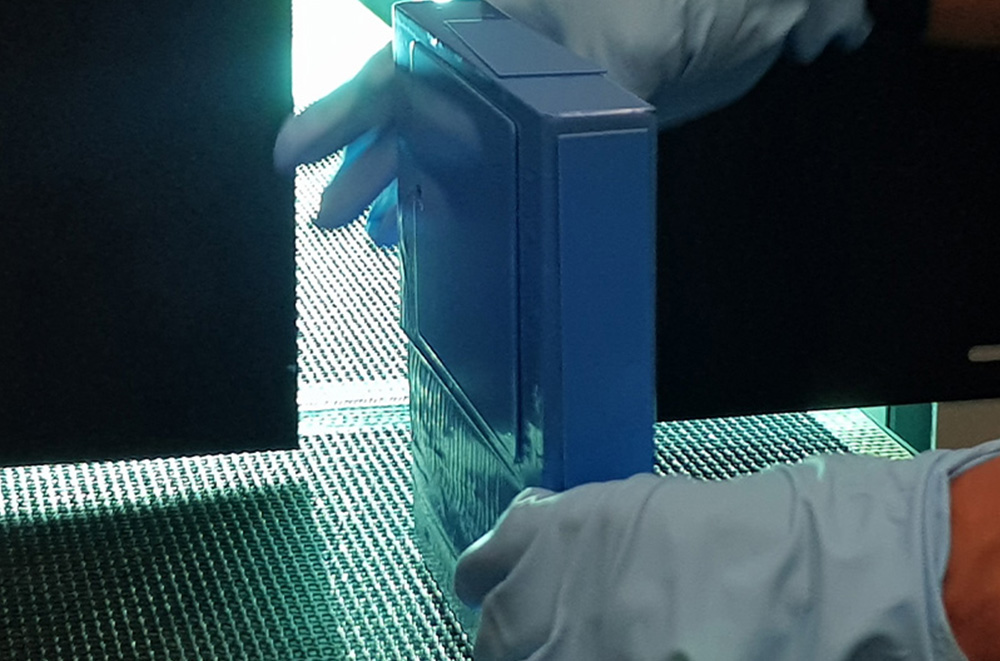

Plasma treatment of a battery cell

Fine cleaning of a battery cell in a PTU (Plasma Treatment Unit) from Plasmatreat in preparation for the subsequent finishing with UV coating.

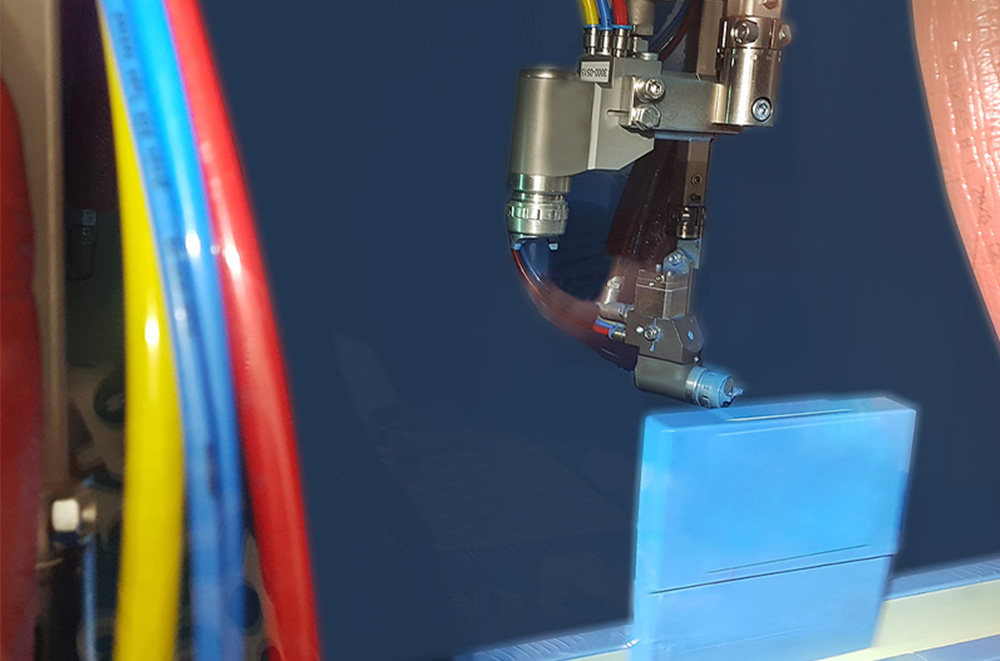

View into the Venjakob spray coating booth

Contactless coating of different battery cell formats without changeover

Outlet from UV channel

Outlet of the battery cell coated and cured with 100% UV coating material, ready for the subsequent processing step

FURTHER TOPICS AT OUR BOOTH

Efficient, fully automatic coating lines for

- cooling plates

- Automotive interior and exterior

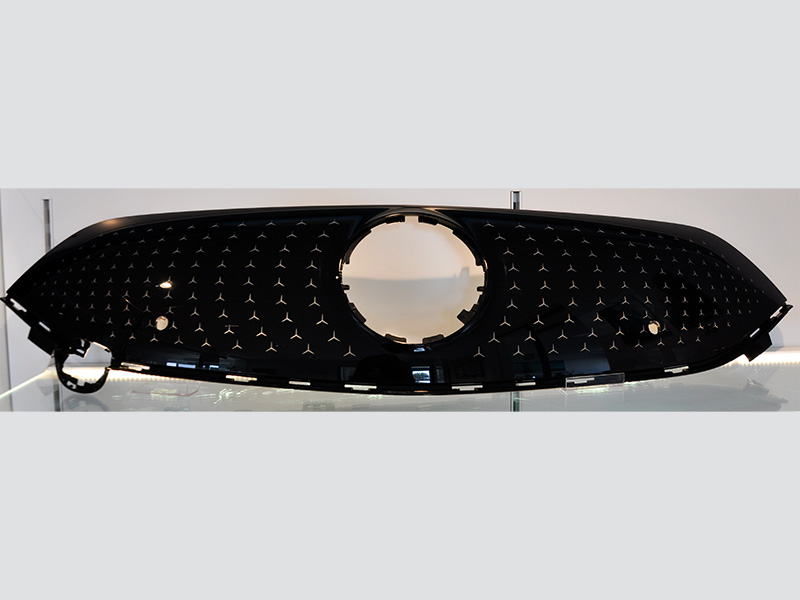

High performance coating line for automobile interior /exterior

Special features:

- for flat and curved 3 D components

- coating in one pass

- suitable for UV-curing systems

- modular system, easy to expand or retrofit

Suitable for applying

- functional,

- decorative and

- effect coatings

Masterpanel

Finishing line for cooling plates

Special features:

- 4-sided coating in one pass

- coating of different cooling plate formats

without conversion

- reliable all-round protection

- increased production speed

- no handling / turning / gripping

- paint recovery system

One suppler for all process steps:

- - pre-treatment (cleaning + activation systems)

- - coating

- - drying/curing

- - material handling

- - exhaust air-purification

Gained your interest? Come and talk to us!

Our team is more than pleased to explain our concept to you and to listen to your specific and individual requirements. Not only for battery cell coating. For task regarding pre-treatment I coating I drying I automation I exhaust air purification as well as automatic bonding technology (bonding, sealing, potting).

We look forward to seeing you!